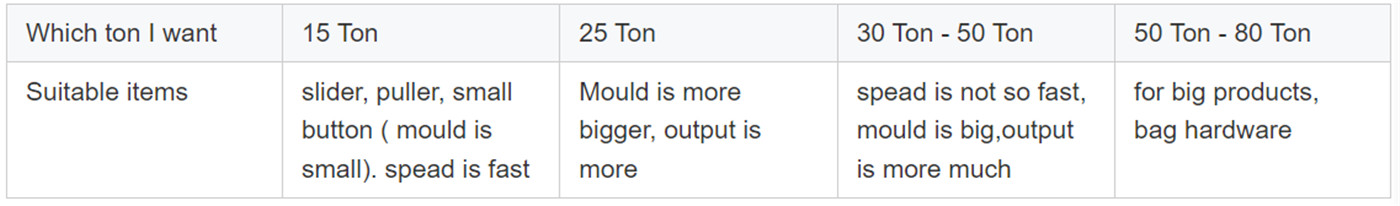

Ukwenziwa Kwesikhunta sangaphambilini kanye nokwakhiwa kwemikhiqizo yamahhala

I-Plastic Injection Molding for Home Appliances

Ukubumba umjovo wepulasitiki kuguqule ukukhiqizwa, okuvumela izinkampani ukuthi zenze kalula izingxenye zepulasitiki ezisezingeni eliphezulu, ezikhiqiza ivolumu ephezulu.Nokho, inqubo yokwenza isikhunta sokujova ingadla isikhathi futhi ibize.Ukubhekana nalezi zinselele, ubuchwepheshe bokuphrinta be-3D buye bashintsha umdlalo, bunikeza izixazululo ezisebenza kahle nezingabizi kakhulu.Kulesi sihloko, sizohlola izinzuzo kanye nokusetshenziswa kokuphrinta kwe-3D kokubunjwa komjovo wepulasitiki futhi sixoxe ngezinsizakalo ezinikezwa inkampani yethu.

Inkampani yethu ingumkhiqizi we-OEM/ODM onguchwepheshe ekwakhiweni nasekukhiqizeni isikhunta sokujova.Siyakuqonda ukubaluleka kokuthuthukisa izinqubo zokukhiqiza nokuqinisekisa ukunemba okukhulu.Ukufeza lokhu, sisebenzisa amaphrinta e-3D asezingeni eliphezulu ukuze sakhe ama-prototypes anencazelo ephezulu.Le mishini esezingeni eliphezulu isilethele izinzuzo ezinkulu, iguqula indlela esiklama ngayo futhi senze isikhunta sokujova.

Inzuzo yokuqala yokusebenzisa ubuchwepheshe bokuphrinta be-3D yikhono lokukhiqiza imiklamo yesampula eyinkimbinkimbi ngentengo ethengekayo.Izindlela zendabuko zokukhiqiza isikhunta ngokuvamile zihilela izinqubo zomshini eziyinkimbinkimbi ezibizayo futhi ezidla isikhathi.Ukuphrinta kwe-3D kusivumela ukuthi sakhe imiklamo eyinkimbinkimbi futhi enemininingwane eminingi ngokuqondile kusuka kumamodeli edijithali, okuqeda isidingo sokusebenza ngokomzimba okukhulu.Lokhu kusivumela ukuthi sinikeze izixazululo ezingabizi ngaphandle kokubeka engcupheni ubunkimbinkimbi bamathuluzi nekhwalithi.

Enye inzuzo ebalulekile ye-3D yokuphrinta isikhunta somjovo wepulasitiki ukuphrinta kalula imiklamo engalungiswa ngayo empukaneni.Izindlela zokukhiqiza isikhunta ezivamile ngokuvamile zidinga ukulungiswa nokulungiswa okuthatha isikhathi esiningi, okuholela ekubambezelekeni kwezinhlelo zokukhiqiza.Nokho, ukuphrinta kwe-3D kusivumela ukuthi sibone futhi sikhombe amaphutha edizayini noma ukuthuthukiswa ngesikhathi sangempela.Ngokuphindaphinda ngokushesha ngezibuyekezo eziningi zedizayini, singanciphisa kakhulu isikhathi esisithathayo ukuqedela ukwakheka kwesikhunta.Lokhu akusheshisi kuphela inqubo yokukhiqiza, kodwa futhi kuqinisekisa ukuthi isikhunta sokugcina sihlangabezana nemininingwane edingekayo.

Ukwengeza, ubuchwepheshe bokuphrinta be-3D busivumela ukuthi sizame izinto ezahlukene futhi sihlole ukusebenza kwesikhunta ngaphambi kokungena ekukhiqizeni ngobuningi.Lokhu kuvumelana nezimo kusivumela ukuthi senze izinqumo ezinolwazi mayelana nokukhetha impahla, siqinisekise ukuthi isikhunta sokugcina sisebenza kahle kakhulu ngesikhathi sokubumba umjovo.Ngokuhlola izinto ezibonakalayo ngama-prototypes aphrintiwe e-3D, singakwazi ukuqeda izinkinga ezingaba khona futhi sehlise izindleko zokukhiqiza zizonke.

Ngaphezu kwalokho, ukuphrinta kwe-3D kukhulisa ukuqina kanye nokuguquguquka kokukhiqizwa kwesikhunta.Izindlela zendabuko ngokuvamile zidinga ukudala amathuluzi angokwezifiso omklamo ngamunye oyingqayizivele, okuholela ezindlekweni ezengeziwe kanye nezikhathi zokuhola.Ngokuphrinta kwe-3D, singenza isikhunta esinobukhulu obuhlukahlukene nobunkimbinkimbi sisebenzisa imishini efanayo.Lokhu kushesha kusivumela ukuthi sihlangabezane nezinhlobonhlobo zezidingo zamakhasimende futhi kusinikeza inzuzo yokuncintisana endaweni yemakethe.

Nakuba ubuchwepheshe bokuphrinta be-3D buletha izinzuzo eziningi ekubunjweni komjovo, kufanele kugcizelelwe ukuthi abukwazi ukuthatha indawo yezindlela zokukhiqiza isikhunta esivamile.Izinqubo zokukhiqiza zendabuko zisadlala indima ebalulekile ekukhiqizweni kwezimboni ezinkulu.Kodwa-ke, ngokuhlanganisa ukuphrinta kwe-3D ekuhambeni kwethu komsebenzi, singakwazi ukuhlela inqubo yokuthuthukisa isikhunta, sinciphise izindleko futhi sithuthukise ukusebenza kahle okuphelele.

Kafushane, inkampani yethu ihlinzeka ngobuhle ekukhiqizeni isikhunta sokujova isebenzisa ubuchwepheshe bokuphrinta be-3D besimanje.Ngobuchwepheshe bethu ekwakhiweni kwesikhunta kanye nokukhiqiza, kuhlanganiswe nezinzuzo ezinikezwa ukuphrinta kwe-3D, singahlinzeka ngesikhunta sekhwalithi ephezulu ngentengo ethengekayo.Ukusetshenziswa kobuchwepheshe bokuphrinta be-3D kusivumela ukuthi sakhe imiklamo yesampula eyinkimbinkimbi, sibuyekeze imiklamo khona manjalo, sizame izinto ezihlukahlukene, futhi sikhulise ukunwetshwa nokuhlukahluka.Ngokuhlanganisa izinzuzo zezindlela zokukhiqiza zendabuko nezesimanje, siqinisekisa ukuthi amakhasimende ethu athola isixazululo esingcono kakhulu sezidingo zawo zokubumba umjovo wepulasitiki.

Imininingwane Yomkhiqizo

| Le yindawo ka Origin | China |

| I gama le-brand | HSLD/ Ngokwezifiso |

| Imodi yokubumba | Abalandeli be-Plastic Injection Mold |

| Izisetshenziswa | CNC, EDM Cutting Machine, Plastic Machinery, njll |

| Impahla Yomkhiqizo | Insimbi: AP20/718/738/NAK80/S136 Ipulasitiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| I-Mold Life | 300000~500000 Amashothi |

| Umgijimi | Umgijimi Oshisayo noma Umgijimi Obandayo |

| Uhlobo lwesango | I-Edge/Pin point/Sub/Side Gate |

| Ukwelashwa kwendawo | I-Matte, ipholishiwe, i-Mirror epholishiwe, ukuthungwa, ukupenda, njll. |

| Isikhunta Cavity | Imbobo Eyodwa noma Ephindaphindayo |

| Ukubekezelelana | 0.01mm -0.02mm |

| Umshini Wokujova | 80T-1200T |

| Ukubekezelelana | ± 0.01mm |

| Isampula yamahhala | etholakalayo |

| Inzuzo | isixazululo esisodwa sokumisa/umklamo wamahhala |

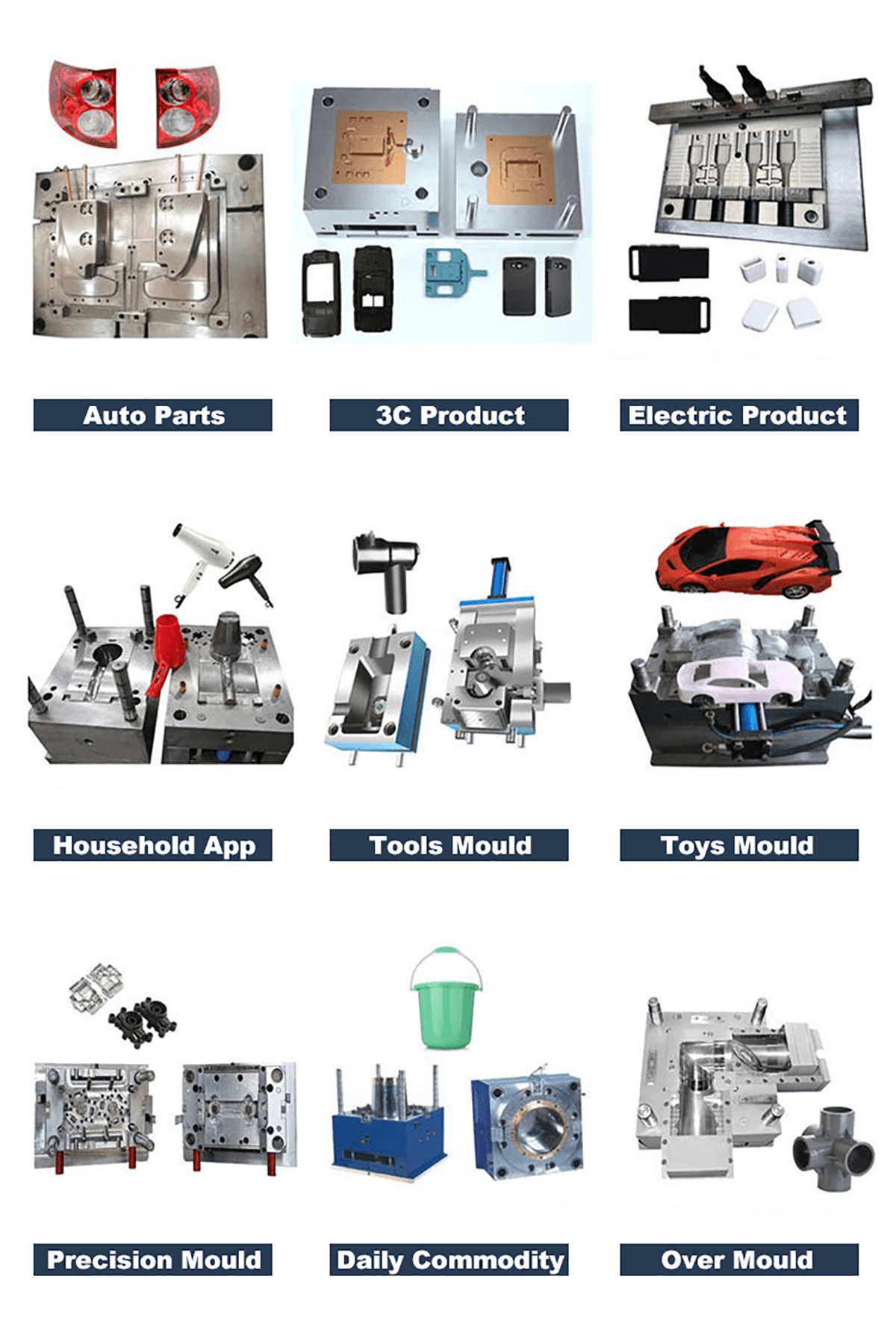

| Inkambu yohlelo lokusebenza | Imikhiqizo ye-elekthronikhi, imikhiqizo yobuhle, imikhiqizo yezokwelapha, Imikhiqizo esetshenziswe ekhaya, Imikhiqizo ye-Auto, njll |

Imininingwane Yemboni

Izibungu ezengeziwe

Ukuthunyelwa

Isevisi yokupakisha ekhethekile yakho: Ikesi lezinkuni elinefilimu

1. Ukuze uqinisekise kangcono ukuphepha kwezimpahla zakho, professional.

2. Okuhle endaweni, izinsiza zokupakisha ezilula nezisebenza kahle zizohlinzekwa.

FAQ

I-HSLD: Yebo, imvamisa izingxenye ezisele zesikhunta se-die casting sifaka isikhunta, uhlaka lwesikhunta, umgogodla wefasitela, umgogodla onyakazayo, ikhanda lombhobho.Ungahlola futhi wazise ukuthi yiziphi izingxenye ezisele ozidingayo.

I-HSLD: Isifaki sethu sesikhunta senziwe nge-DAC.

I-HSLD: Ingqikithi yethu ehambayo yenziwe nge-FDAC.

HSLD: Yebo.

I-HSLD: Imishini ehlukene inokunemba okuhlukile, ngokuvamile phakathi kuka-0.01-0.02mm